Insulation

Our solutions for the insulation board industry

Schermesser Gmbh expands its activities in the insulation board industry

You are an industrialist in the field of insulation panels, and you wish to modify your production lines or develop new ones?

Opt for Schermesser’s solutions

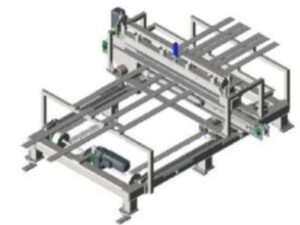

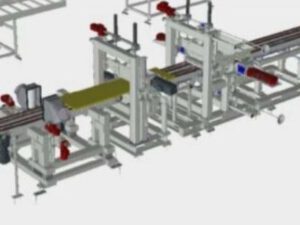

Our adapted and tailor-made production systems meet your production criteria. Whether handling or machining, Schermesser offers you productive and competitive systems (refer to our special machines). Contact us to receive more information about our services available across the world.

The panel industry, our core business

With more than 40 years of experience, our highly qualified teams assemble and manufacture various machines specialized in the panel industry, including wood, metal and insulation.

Driven by our passion for the industry, we are today a strong partner, delivering solutions with state-of-the-art precision for your production lines. In accordance with your desire for development and innovation, we respect your budget.

Future-oriented solutions for your insulation panel production lines

Mineral wool (glass wool or rock wool), plastic insulation or wood fiber insulation, we listen to your need for handling solutions and plan your project together.

Whether your plastic insulation products are PIR, PUR, EPS or XPS, we provide you with special machines adapted to the panels you manufacture.

Schermesser: your solution provider

You wish to modify an existing production line: Our systems are adaptable in order to optimize and renovate your lines. We assure you to be able to make your machines evolve and progress in order to have the latest technologies available on the market.

You invest in the construction of new lines: Our design office meets your requirements and designs rigorous specifications. Thanks to our German engineering we guarantee you production lines that conform your expectations.

How do we manufacture our machines?

It is in France, in Guewenheim, that the magic happens. Our highly qualified employees, with extensive experience in the industry, carry out meticulous work to deliver a result that exceeds your expectations. Welding, assembling, painting and assembling we manufacture the product from A to Z in our workshops.

Our facilities are equipped with controls produced in our factories in France. Planning, cabling, assembly and programming are carried out by our team. In this way, we guarantee you maximum system availability and reliability.

Our priority, the satisfaction of our customers

In order to ensure the reliability and durability of our machines, we test them in our workshop to guarantee you a reliable and high-quality final product. A project is completed when the customer is satisfied. Today and since its inception, Schermesser’s strategy has been forward-looking.

A climate of trust and transparency towards our clients is essential in order to carry out long-term projects. We accompany you throughout the installation cycle of your systems. Maintenance, replacement parts and personalized assistance are available 24 hours a day, 7 days a week.

Safety and compliance with standards

We strongly insist on safety between human and machine. The systems we sell ensure a high level of safety for the people who use them. All our machines comply with the standards in force and guarantee optimal safety. The equipment is tested and verified in our workshops in order to deliver you a reliable product.

The demand for eco-responsibility

At Schermesser, we are aware of environmental issues. We act in an ecological and sustainable way. We are now committed over the long term to optimizing our production by reducing our energy consumption, respecting the environment and preserving natural resources in the course of our activity.

In this way, we combine expertise, ambition and responsibility to jointly develop efficient solutions to reduce the impact of activities on the environment

Opt for German quality

Because our customers deserve the best. As manufacturers, we deliver innovative machines that keep their promises. Our manufacturing systems and industrial processes follow a rigorous methodology. Our processes allow our team to work in a secure work environment in order to achieve a flawless final product while respecting deadlines.

We supply you with complete systems for the processing of insulation boards, but also with individual machines to integrate them into your existing production systems. Our qualified team with a large experience in the field of industrial installations allows the integration of machines in a short period of time.

Our machines:

- Cooling lines

- Stacking lines

- Sawing lines

- Sanding lines

- Automated storage systems

- Brush cleaning device

- Roller conveyor